THE DISHWASHING AREA OF TOMORROW: MOTIVATIONAL AND COST EFFICIENT

Would you like to have a dishwashing area that truly meets your needs?

With high productivity and logical workflows? With technology that is economical, efficient and ergonomic for your employees? All of this is possible – with professional planning.

We use our expertise to bring together hygiene, efficiency, ergonomics and economy to create the ideal workflows in your dishwashing area. Every dishwashing area is unique and needs unique equipment. This applies to plans for new builds and renovations alike.

Planning with plenty of experience!

- Almost 100 years of experience manufacturing warewashing and conveying technology for commercial kitchens

- 40 years of experience in food waste treatment systems

- Almost 100 years of experience in cleaning and disinfecting medical devices

ARE YOU PLANNING A NEW DISHWASHING AREA? OR WOULD YOU LIKE TO RENOVATE YOUR EXISTING ONE? MAKE SURE YOU CONSIDER:

IMPORTANT INFLUENCING FACTORS WHEN PLANNING A DISHWASHING AREA

- The size of your food service business (outdoor and indoor areas, number of covers)

- Guest turnover (covers per hour)

- Type (table service, self service, buffet)

- Occupancy rate (in general operation and at peak times)

- Space available

- What washware is produced? High variation in table dishes? Fine glassware and porcelain, cookware?

- Does it make sense to use a partially or fully automated dishwashing machine?

- Dish return: self-service, tray trolleys, conveyor, table clearers, waiting staff, handling food and drink waste, chaotic or orderly return set-up

- Food waste management: what kinds of food waste are produced? How many points in the dishwashing area deal with food waste? What is the structure of the building services engineering? What are the legal requirements?

- Dishwashing: machine configuration, water quality, drying

- Handling dishes post wash: quality control, storage, reuse

- Equipment in the cycle: dish racks and cutlery quivers

- Storage/reordering of cleaning agents

- Workflows: dish routes, staff routes, food waste management, other waste management, equipment in the cycle

- Hygiene: standards and guidelines, staff hygiene, machine (maintenance and care), quality control on washware, handling food and other waste, ventilation

- Employee rotas

- Food waste management: what kinds of food waste are produced? How many points in the dishwashing area deal with what volumes of organic waste? Is there particular legislation to consider?

THE MOST COMMON MISTAKES ARE TO DO WITH:

- Space requirements

- Use of dishes

- Staff

- Machines

- Hygiene standards

- Correct water treatment

- Perfectly tailored chemicals

- The right racks

- The right organisational aids (tables, distribution trolleys, inclined shelf)

- Utility costs

- Legal requirements on drainage, ventilation and removal of grease from waste water

NO COINCIDENCE: THE PERFECTLY PLANNED DISHWASHING AREA

Poor planning can rapidly cost thousands. Experienced, specialised planners and other professionals will put together the best possible design for your dishwashing area. You can spot errors if:

- The clean and dirty sides are not separated

- There are too few storage surfaces

- Routes overlap

- The ergonomics are inadequate

- Ventilation is insufficient

- The warewashing technology is the wrong size

- Poor design for simple and hygienic food waste management.

- Too little automation

- Errors in logistics

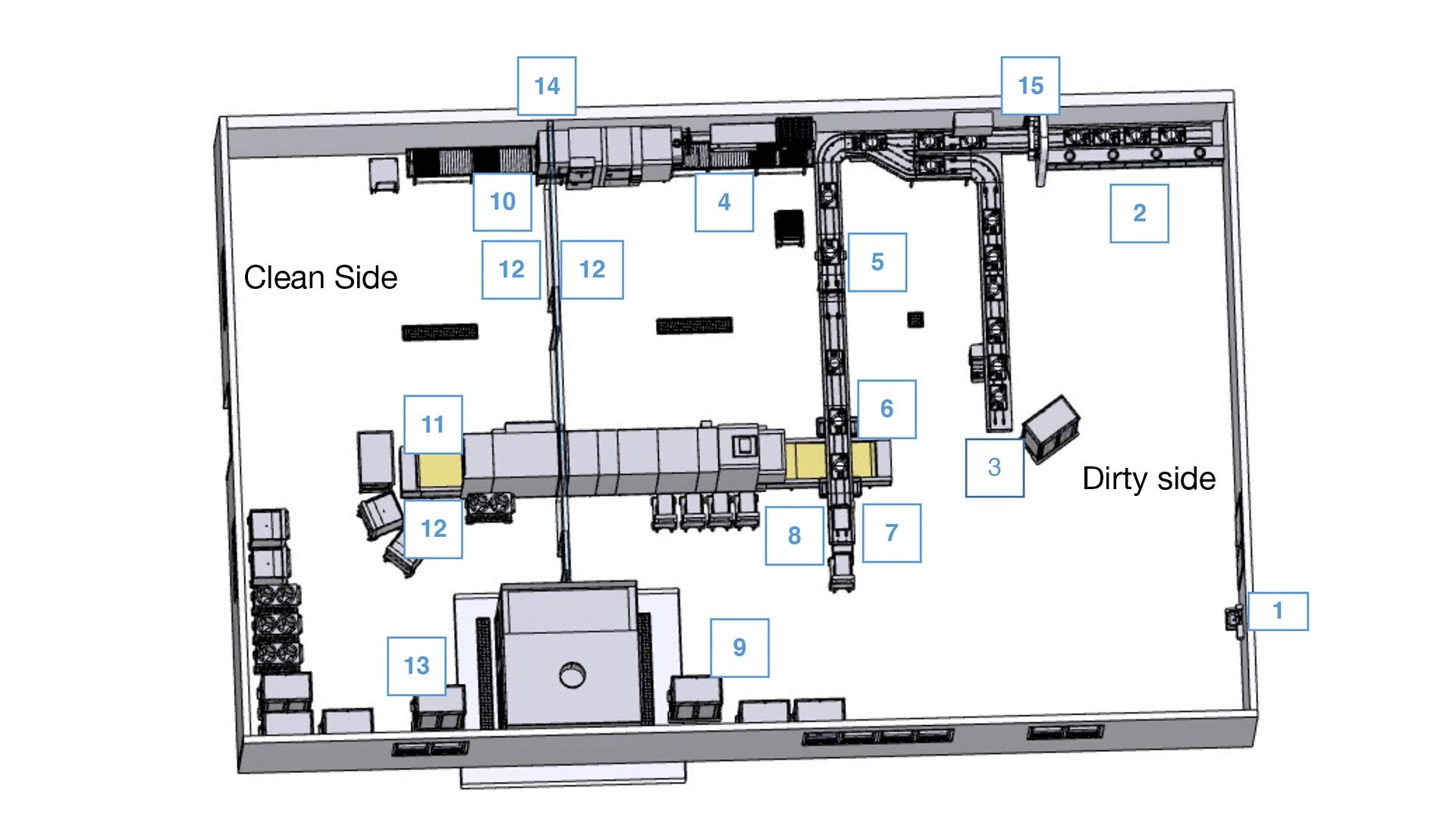

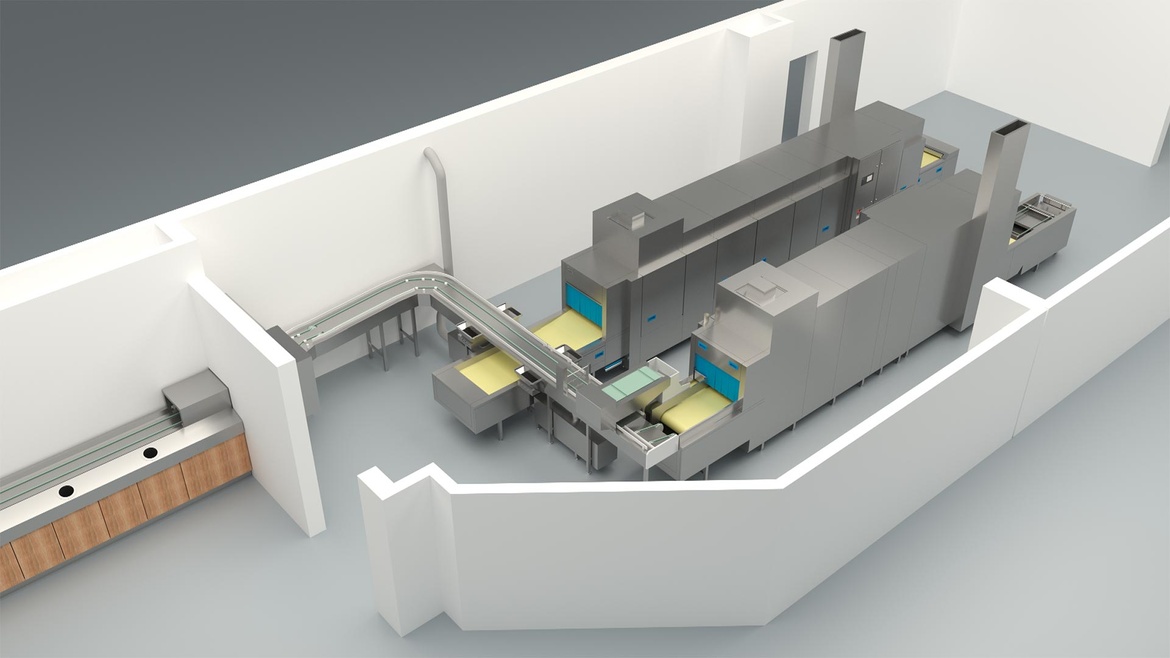

Come with us and take a look at a large dishwashing area in a hospital. Here, we present you with an idea of what a dishwashing area can look like. In this case, the staff dining room is right next to the kitchen and the dishwashing area.

We know no limits.

Even more could be done in the dishwashing area – e.g. a partially automated system with a separate cutlery and tray track, and the building blocks of automation like cutlery sorting systems, plate stacking devices and ergonomically positioned infeed stations for organic waste. If the staff dining room is on a different floor, then we use vertical conveying technology to transport tableware to the dishwashing area. We make your dreams reality.

SEPARATING CLEAN AND DIRTY:

the main purpose of the dishwashing area is hygiene safety – for patients, guests and staff. Clean and dirty items cannot mix. That would risk pathogen transmission. The golden rule: strict separation of the clean and dirty sides.

Dirty side

- Always wear clean disposable gloves on the dirty side so as to avoid recontamination or pathogen transmission

- Avoid crossing over to the dirty side

Clean side

- Always wear clean disposable gloves in this area so as to avoid recontamination or pathogen transmission

- Hand washing and sanitising options or the opportunity to change gloves must be provided on the dirty/clean side (12).

- On the clean side, the rule is: unload clean washware wearing clean disposable gloves.

- Keep the clean side clean

- Avoid crossing over to the dirty side

Hand wash basin and dispensers for paper towels, disposable gloves and hand sanitiser. Hand washing and sanitising options must be provided.

Also, plan in enough buffer space here for tray carts to arrive.

Dirty dish and tray return from the staff dining room using the bi-cord conveyor. We are using this hospital as a case study but this works equally well for communal catering in staff canteens and department store cafés.

Delivery of dirty, and sometimes contaminated, dishes and trays from patient meals using tray carts. Employees remove waste such as serviettes and milk packaging from the trays and dispose of them immediately in the rubbish bins provided.

The tray carrying the dirty dishes is placed on the conveyor. Next, the two tracks of the bi-cord conveyor converge using a tray merge.

If the tray carts are empty, they are taken to the cart washer and washed (9).

If the trays are to be cleared of organic waste, paper and plastic earlier, on the tray conveyor, then WTS-AK infeed station is placed by the conveyor instead of the rubbish bins. Organic waste can be disposed of here, easily and ergonomically, right where it is generated. The food waste is automatically removed using suction and then stored in a storage tank once homogenised.

Top ergonomics tip

- Everything needs to be easy to reach from the entrance

- Short routes mean improved productivity

- No staff routes should cross, that way work processes stay fluid

- Regularly carrying heavy dishes is a strain on employee health, so use carts instead of carrying dishes

The trays move on from the bi-cord conveyor to the M-iQ.

Flight type dishwashing machine

Before this, an employee (5) removes the glasses from the tray. These are then washed in the UPster K rack type dishwashing machine.

Top ergonomics tip:

heat recovery systems in the dishwashing machines provide a pleasant indoor climate. Less moisture, less mould.

Providing a conveyor gate means that employees do not have to go through the clean side or leave the room, they can stay on the dirty side. Conveyor gates mean shorter routes and are also important when planning emergency escape routes.

This is where employees feed the food waste from the plates straight into the WTS-AM infeed stations on the WasteStar FC. From there, it is fed through a closed system into the cellar, ground down and stored in an odourless tank system. Now, the liquefied mass has been ideally processed for a tanker to take it to a biogas plant.

The dishes are fed straight onto the finger conveyor on the M-iQ flight type dishwashing machine where several people can work.

Cutlery is loaded vertically into cutlery baskets and placed in a cutlery soak trolley for pretreatment. The empty tray continues and is automatically

stacked by the tray stacker. Depending on the volume to be washed, it may only be washed later on.

Top ergonomics tip:

The WTS-AM features four chutes to offer maximum flexibility at all points on the conveyor and path through the dishwashing machine. This means there are no food waste bins in this area and the workflow makes it simple for employees to remove dishes from the trays and scrape food straight into the chute before placing the washware on the conveyor.

The employee in the cart washer area ensures that the tray carts are always washed and made ready for use again (at 3)

Sectional drawing of hospital

After the wash cycle, the clean glass racks are temporarily stored on the discharge roller table. This works as a buffer zone. Using demineralized water (from the integrated reverse osmosis system) achieves an incredible washing result. Good for hygiene and ergonomics: there is no need to polish with a tea towel, thus minimising the risk of recontamination.

Washware from the flight type dishwashing machine is placed straight into the pre-prepared dispenser cart. When tray carts emerge from the cart washer after the washing and drying process, they are sent to the ‘cart park’.

TOP ERGONOMICS TIP:

TOP SAFETY TIP:

TOP HYGIENE TIP:

TOP ECONOMY TIP:

PLANNING AIMS:

- Efficient, quick and practical work processes

- Examine options to introduce automation

- Improve productivity

- Comply with legal requirements

- Protection at work: protect staff from contaminations and improve ergonomics – reduce level of sick days.

- Attain high hygiene standards

THE DISHWASHING AREA AS A BUSINESS FACTOR:

can a dishwashing area be profitable?

Take a close look at the operating costs in your dishwashing area. Purchasing warewashing technology accounts for around 8%. If you buy innovative warewashing technology, it pays for itself within a few years. Payroll costs make up 15% of the total. That is one more reason to plan properly for productivity.

GOOD ERGONOMICS FOSTERS GOOD EMPLOYEE HEALTH

Clever kitchen planning does not just factor in efficiency, but employee health, too. Labour supply is tight in the food service sector. A workplace equipped for ergonomics improves employee satisfaction and reduces sick days.

Make sure you:

- Do not make routes too long

- Provide an ergonomic working height

- Reduce lifting and twisting movements (no more than 90°)

- Use automation to benefit employee health (plate stacker, conveying technology, food waste treatment system)

- Ventilate the room

- Use heat recovery systems (in the warewashing technology)

- Reduce noise

VENTILATION IS PARAMOUNT

We've established the process for hygienic, ergonomic and efficient warewashing and sustainable food waste collection. But heat and humidity determine the indoor climate and therefore ergonomics of the workplace. Moisture can condense on cold patches of the wall and cause mould.

Make sure you:

- Equip the kitchen/dishwashing area with a ventilation system suited to its size

- Any poor positioning has a dramatic impact on the indoor climate in the kitchen

- Use a modern dishwashing machine with an integrated heat recovery system to avoid steam and unnecessary moisture

- Contract expert planners

TAKE A LOOK AT THE TECH IN USE

TRAY RETURN USING BI-CORD CONVEYOR.

Planning:

- Dirty dishes arrive in the dishwashing area automatically (no additional staff to move the dishes around)

- Napkin chutes provided near the tray return (less work for dishwashing staff)

- Efficient and quiet and transport process

- Low-maintenance and easy-to-clean bi-cord conveyor

TRAY MERGE

Two tracks merge into one – this is a simple way to get all of the tableware into one place.

Planning:

- A solution focused on the use and the space, e.g. using two bi-cord conveyor tray return stations

- The conveyors continue running while merging. No time is lost

- Up to 30 trays per minute can be merged onto one conveyor

WasteStar FC INFEED STATIONS

Infeed stations for leftovers and organic kitchen waste – boosting hygiene by using a closed system. The WasteStar FC food waste treatment system is installed in the hospital basement. This is where organic kitchen waste and leftovers are sustainably collected, ground down and stored.

Planning:

- No need to connect to the waste water system

- No need for a chilling system

- Custom infeed stations right next to the bi-cord conveyor (saves additional journeys for staff)

- Hygienic due to the closed system (no odour)

- The WasteStar FC's modular and versatile system means that the food waste management plan for your dishwashing area can be adapted to the needs of the space and your business

- Sustainable: fewer waste disposal journeys (approx. 50%) as compared to an organic waste bin. Homogenising food waste increases biogas yields by up to 20%.

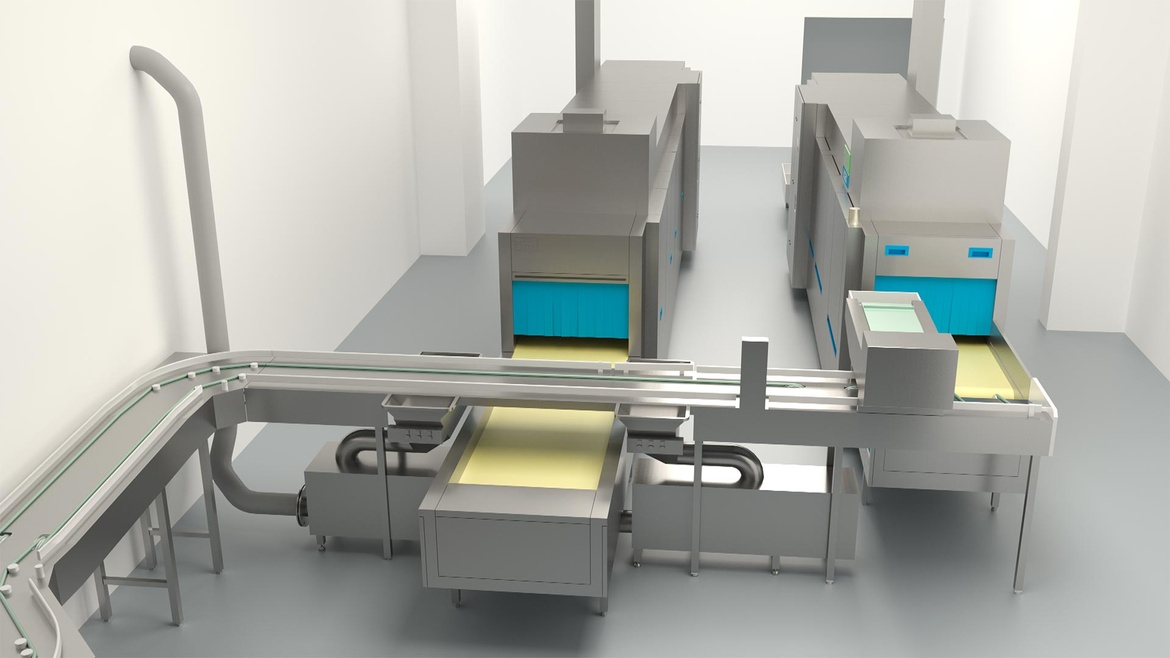

UPster® K RACK TYPE DISHWASHING MACHINE

In our case study, the UPster® K only washes glassware. The integrated osmosis system removes the need for labour-intensive polishing and minimised recontamination from tea towels. The integrated heat recovery system removes the need for a ventilation connection.

Planning:

- The compact, modular structure makes for flexibility in how to install it

- Automatic corner infeed

- 90° and 180° curves, tables and roller conveyors

- Up to 210 racks per hour

- No additional air vents required

- Models in different sizes

M-iQ FLIGHT TYPE DISHWASHING MACHINE

Clean, economical and sustainable – the M-iQ range of dishwashing machines. But it is much more, too. The glass display is intuitive to operate and the blue operating concept facilitates simple human-machine communication, streamlining workflows. The intelligent design for the air channel system incorporates heat recovery and provides the option to feed exhaust air directly into the room. The M-iQ filter actively strains out dirt from all wash zones, keeping the wash water extra clean.

Planning:

- Modular structure makes for flexibility of installation

- Intelligent AirConcept with heat recovery system means no need to connect to the ventilation system

- View hygiene data using MEIKO Connect

- Models in different sizes: conveyor widths and passing heights

- Automated versions for trays and cutlery

CART WASHER (CUBICLE WASH SYSTEM)

Hygienic cleaning and decontamination of carts at the push of a button.

Planning:

- Large wash chamber (M, L, XL) – depending on size and number of carts

- Front or through loader (to help maintain consistent separation of dirty and clean sides)

- Multifunctional, can be used for a range of washware (stock cage trolleys, heated food trolleys, etc.)

Why you are best off contracting expert planners:

- They are aware of legal requirements and will ensure compliance

- They take into account planning parameters such as hygiene, ergonomics, safety and efficiency

- They know what different professional kitchen appliances and dishwashing machines have to offer in terms of capacity, quality, maintenance costs and sustainability

- Planning errors are expensive and inefficient