MEIKO CONVEYING TECHNOLOGY

Up, up and away with conveying technology

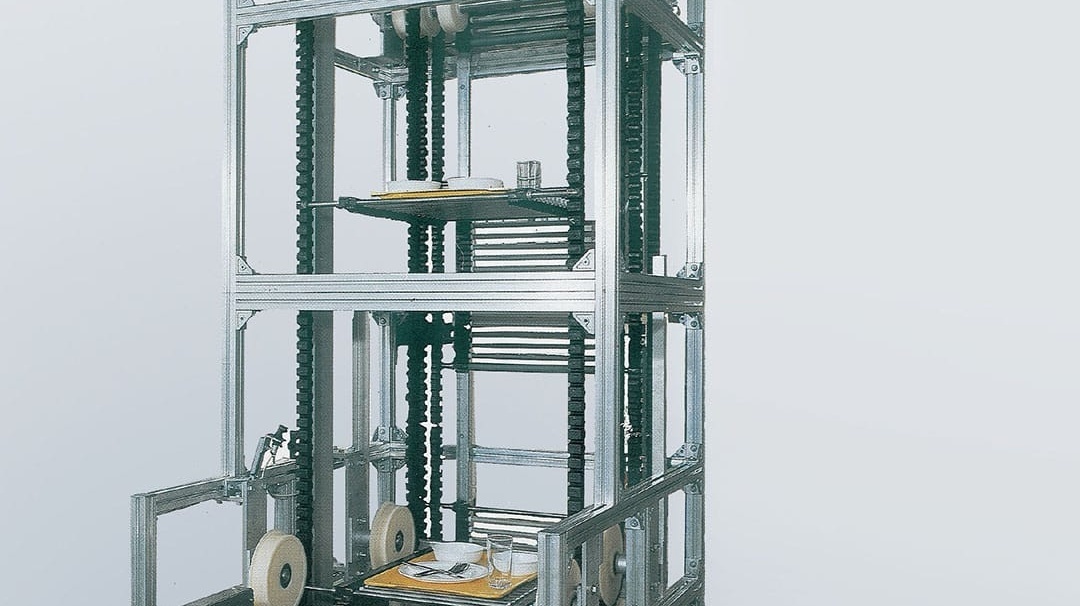

3 floors up, 50 m across: MEIKO conveying technology transports dirty or clean washware vertically or horizontally. Dishes, containers, racks, trolleys, carts... We have vast experience in this area: highly complex conveyor systems with monitoring devices can only work with clever concepts and solutions in terms of the technology and how it all works. Regardless how tricky your space may be, we can optimise your processes, minimise costs, improve hygiene and provide ergonomic working conditions.

QUALITY

ANSWER: approx. 200 m

The system is set up for 5,000 diners and runs across several floors.

The conveying technology at Vodafone uses both horizontal and vertical conveyors that lead straight into the dishwashing area. The dirty dishes pass from one floor to the next en route to their destination, with the conveyor belt running along hidden tunnels beneath the restaurant ceiling. Junctions and points are used to bring the various conveyor belts together into a single direct line to the dishwashing area.

SUSTAINABILITY

Our conveying technology plays this role: no more hard work pushing chock-full dish trolleys around different floors and on to the dishwashing machine. Diners simply place their tray carrying their dirty dishes and leftovers onto the conveyor. Clever constructions keep the service running: if a round belt is out of order, just that part can be switched out and spot welded. The system keeps running...

HYGIENE

That is, keeping the round belts to the specific points where they make contact with the surface, keeping the whole conveyor table accessible for cleaning. This is especially important at the collection and clearing points, where it creates ideal conditions to help you maintain the hygiene requirements for commercial kitchens.