WELCOME TO THE PERFECTLY PLANNED UTILITY ROOM!

The utility room is vital in managing and caring for bedridden patients. This is where care utensils and other instruments are hygienically cleaned and maintained between uses.

This room must be carefully designed, right down to the details, in order to play its important role in preventing infections and to integrate efficiently into the care staff's workflows.

With over 90 years of experience in medical devices, we know the critical points in the utility room and how the processes should ideally work – so we can lay the groundwork for improved hygiene and protection at work in the planning and design phase.

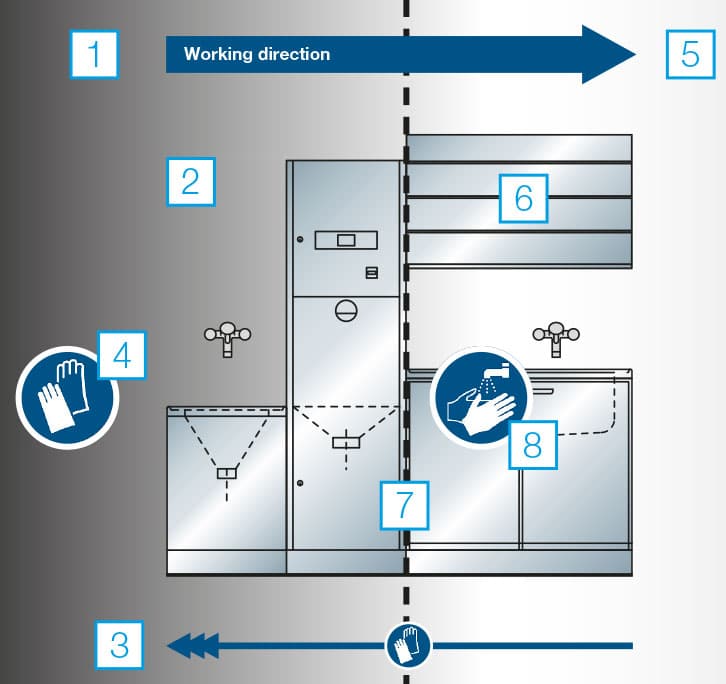

THE FOUNDATION: SEPARATING CLEAN AND DIRTY

The planning process is based around separating a clean and a dirty area. A clean area should be planned for storing disinfected care utensils.

The dirty side:

- This is where used, contaminated care utensils and other instruments are collected.

- This side contains everything needed for disposal, maintenance and cleaning (disinfection appliances, slop sink units, etc.)

- Routes must be short and the appliances must be easily and quickly accessible, i.e. close to the entrance.

- Disposable gloves are worn for all work in this area.

Planning goals:

Protecting staff – contact with used, contaminated utensils must be minimised.

The clean side:

- Only cleaned and disinfected care utensils and instruments are present on this side.

- This area mainly contains shelves and cupboards for hygienic storage.

- The dirty side must not be overlapped or crossed.

- Provision is required for washing hands and changing protective gloves – either close to the cleaning and disinfection appliance or near the exit.

Planning goals:

Prevent recontamination – utensils which have already been cleaned and disinfected must still be hygienically safe next time they are used.

Further key considerations:

- When choosing a room, ensure it has a window for direct ventilation.

- Flooring must be non-slip and feature as few joins as possible.

- The entire room, including all surfaces, should be easy to clean and disinfect.

- Small gaps are to be avoided as there is no access to clean them.

EQUIPMENT: THE COMPONENTS OF THE IDEAL UTILITY ROOM

Just a MEIKO cleaning and disinfection appliance is not sufficient for a functional utility room. You will also need sufficient work surfaces, storage spaces, slop sink units and waste containers to ensure that processes can run optimally. We offer a wide range of these furnishings, too – made in tried and trusted MEIKO quality.

That means:

- We favour using stainless steel for hygiene reasons – stainless steel surfaces have a bacteriostatic effect and are easy to clean and disinfect.

- We take into account ergonomic considerations, providing the ideal working height and entry height using base frames, adjustable feet, floor-standing units, etc.

- We connect the individual components so as not to leave any unhygienic gaps or hard-to-clean corners. Seamless wall connections, flat rims (upstand on table top connecting to wall) with hygiene buffers and sealed surfaces are all brand distinctives for us.

Take a look at this schematic showing the planning for a model utility room and the construction requirements to be fulfilled.

These machines empty, clean, disinfect and dry filled and contaminated care utensils – at the push of a button; in a sealed, vapour-impermeable system; with an adjustable A0 value (60 to 12.000) and short run times.

Planning:

- Close to the entrance to keep routes short

- Floor-standing unit with ergonomic entry height

Options:

- Also available wall mounted for easy floor cleaning, as a cabinet model for added work surface or as an integrated unit in a wet room to minimise journeys

- Available with an automatic door for contact-free opening and closing using a hand sensor or foot switch

- Available with a detergent dosing unit for especially dirty care utensils

For all kinds of items that are used on the ward and need to be cleaned and disinfected – e.g. care aids (kidney dishes, wash bowls, etc.), vases, trays and children's toys.

Also excellent for precleaning and disinfecting instruments used on the wards which must be cleaned before being sent to a central sterilisation unit.

Planning:

- Cabinet model for under a worktop to provide additional work surface

- Close to the soak sink

Options:

- Also available with chemical-thermal disinfection capabilities, e.g. for heat-sensitive items like surgical clogs

- Also available as a tower with a base cabinet for storing containers for detergent and chemical disinfectant

For disposing of slops

Planning:

- With splash guard for reliable protection

- With tap (for water, e.g. to fill cleaning buckets)

- With lockable base cabinet (for chemical canisters or similar)

Options:

- Also available with spiral slop sink flushing using two self-cleaning, easy-to-remove water jets (whirl effect)

For tough dirt

Planning:

- Close to the TopClean 60

- With base cabinet (for storage)

For small items, e.g. used, contaminated protective gloves

For hand hygiene following contact with used, contaminated care utensils

Planning:

- Close to the door (for use when leaving the room)

- Or, alternatively, close to the cleaning and disinfection appliance

- Easy access

- With dispenser for hand sanitiser, soap, protective gloves, paper towels

- With mixer tap, which can be operated using an arm or elbow, or contact-free using a sensor

- With waste paper bin for paper towels close by or integrated into base cabinet

Things you should know: hand hygiene

Cleaned, disinfected utensils must never come into contact with dirty hands. That would contaminate them, increasing the risk of spreading infection. Hands must therefore always be sanitised before touching cleaned, disinfected utensils.

For hygienically storing cleaned, disinfected care utensils until they are used again

Planning:

- Close to the cleaning and disinfection appliance for practicality

For disposing of paper towels and other items

To provide storage for ward equipment and stocks

PREVENTING INFECTION USING ISOLATION ROOMS

A well planned utility room will, as far as possible, use automation to safely clean all care utensils and other instruments coming from the patient's room. The only manual carrying necessary is just across the corridor. This is the only point at which there is a risk of contamination.

Yet even this risk can be reduced in the case of care utensils by installing the cleaning and disinfection appliance in the patient room itself, above the toilet (MEIKO TopLine 30 WC). This means there is no need to carry utensils through the corridor, removing this potential source of risk. Instead, the nursing staff can clean the care utensils immediately after use, right in the wet room attached to the patient's bedroom.

This is one of the most significant and efficient ways to prevent the spread of infection or even an outbreak – which is why it is the preferred method in isolation rooms and isolation wards, where is it particularly important that full, potentially contaminated care utensils do not leave the isolation area.

THINGS YOU SHOULD KNOW: WORKFLOWS IN CARE UTENSIL MANAGEMENT

What are these workflows with a MEIKO cleaning and disinfection appliance? In these videos we show you step by step: how do you handle a bedpan after it has been used by a patient? Where can errors be made?

Watch now:

WHITE PAPER CLOSTRIDIOIDES DIFFICILE

Download here:

THINGS YOU SHOULD KNOW: MEIKO TECHNOLOGY

Read more: